Limited access is a sunshade term that covers a dozen frustrations: low headroom under mezzanines or skybridges, confined courts girded by glazing, soft soils behind historic facades, healthcare facility wings where vibration is actually restricted, basements threaded along with electricals, and retail floors that may not turn off during organization hours. When an industrial property requires deep foundation repair or even brand new assistance in those conditions, typical drilled shafts and also steered piles usually are actually not a possibility. Micropiles, helical piles, as well as resistance piles step into that void. The tools is actually compact, the spoil is actually minimal, and the work can wage surgical preciseness if the crew takes the appropriate methods.

My intent listed here is actually useful. I will walk through how we pick between micro pile, helical pile, as well as resistance pile bodies, the gears and tooling that in fact accommodate with a door, just how we stage grouting as well as load transactions in tight fourths, and also what to expect along with quality control. In the process, I am going to pull examples from work where commercial foundation stabilization needed to thread the needle in between structural demand and functional constraints.

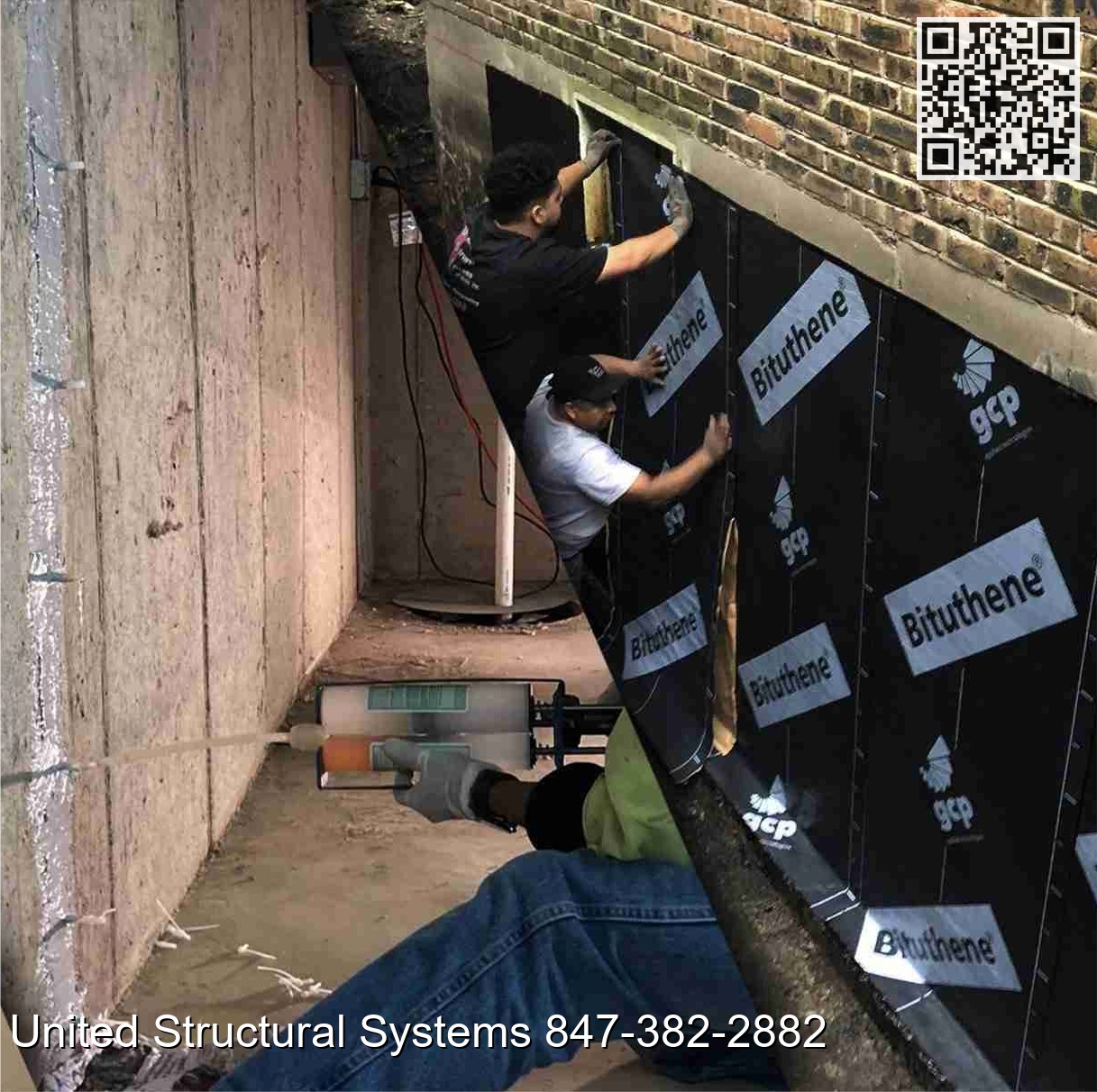

Where micropiles beam in office work

Micropiles are small diameter, high capacity taught aspects, generally 4 to 12 inches, that develop capability largely by means of grout-to-ground connection and also secondarily with steel encouragement. They endure unsatisfactory dirts, may be canvassed with obstructions, as well as could be put in at any kind of slant. In commercial foundation repair they are the best flexible answer when subsurface ailments are actually intricate, overhanging restrictions are actually extreme, or even the lots course should bypass affected masonry or even gently enhanced slabs.

A midtown collection retrofit comes to mind. Our team possessed 8 feets of clearance under a waffle slab, pillars presenting distress from differential negotiation, and a puzzle of avenue. A traditional rig would possess transformed the ceiling right into Swiss cheese. Our team propelled a 10,000 foot-pound limited access practice on a skid, prepared short-lived canvassing by means of stuffing and also block junk, as well as bored to heavy sands at 46 feet. Connection size was 20 feet with cool grout at a water concrete proportion of 0.45. Each micropile held 120 kips in compression after proof testing. The collection kept open, and the janitorial personnel was a lot more concerned regarding dirt than noise.

Micropiles succeed when:

- Subsurface is various, consisting of filler, cobbles, or interbedded coatings, and also you require to case via top scrap to reach experienced stratum. You must put up struggling piles for reversing resistance or to dodge utilities. You requirement expected functionality under both compression as well as tension, like for escalator primary retrofits or even canopy columns with uplift. Vibration limitations are meticulous, like medical facilities and also records centers, where steered systems generate improper risk.

How helical and also protection piles suit the restricted gain access to toolbox

Helical heaps and also protection piles carry lots by means of different mechanisms as well as installment approaches. Both are common in commercial foundation stabilization, specifically when indoor accessibility is precarious and you would like to avoid spoils.

Helical heaps are actually torque-installed steel components along with helices that screw right into the ground, producing ability associated to installment torque. They are actually fast, silent, as well as relatively easy to fix. Helical anchors and helical tieback anchors stretch that concept flat or even at a superficial batter for side and also uplift assistance. In a retail store on a slab on level, helical piles could be put up with an electricity or even gas ride head on a skid steer or transportable mast, travelling through a 36 in door. When dirts are actually cohesive as well as without sizable impediments, a helical pile can carry 30 to 100 kips every element with marginal clutter. For commercial helical pile installation we generally intend around torque of 4 to 12 kip feets for illumination to channel lots, as well as 15 to 30 kip feet for heavier pillars, depending upon shaft and also helix geometry.

Resistance heaps, additionally named push boat docks or even mounted stacks, are actually driven by utilizing the establishment's weight as reaction. We mount steel pipes sector by section until they bear upon proficient material, at that point lock them off along with a brace. In commercial resistance pile installation, they beam for deriving perimeter footings where you can easily brace a jack. They operate inadequately when the structure is too light to steer to refusal, or even when access for a jack as well as frame is blocked out. In the correct setting they offer precise control of lift during the course of structural foundation repair, including small releveling with dial gauges and laser levels.

For deep foundation repair in a mixed-use structure, it prevails to integrate bodies. Helical tieback anchor installment maintains a failing cellar wall structure. Micropiles hold gravitational force lots coming from a new column line inside. Resistance piles underpin an outside footing that is close to quality and effortless to get access to. Each tool has its domain name. The ability hinges on matching it to the ground and the accessibility constraints.

Choosing between systems under tough constraints

Selection starts with load and soil, after that folds in get access to and schedule. For an offered pillar or wall, I consider lifeless and also live lots, a reasonable element of safety and security, seismic need if found, as well as any kind of uplift or sidewise components. At that point I level in website inspection: monotonous logs, SPT strike calculates, any kind of CPT records, and an utility check. Ultimately, I overlay truth constraints: door distances, corridor turns, piece fullness, allowed working hrs, and vibration limits.

If the site needs piercing by means of loaded with debris, or the lots is higher relative to the footprint, micropiles have a tendency to gain. If the grounds are moderately consistent clay-baseds or even sands without sizable cobbles, helical piles or helical anchors are a lot faster. If the building gives enough response, protection stacks can be inexpensive for underpinning.

There are side instances. In reduced headroom cellars along with stiff clay-baseds, helical tiebacks can easily substitute soldier pile as well as lagging, preventing center exploration via pieces. In saturated sands, helical piles can easily spin without evolving to target twist because pore tension rises. Because instance, a predrill to 4 inches size aids, or you shift to micropiles along with threaded bar. In carbonate surfaces with voids, I steer clear of helical piles, due to the fact that coils can easily unite as well as offer an untrue sense of capacity.

The gears that in fact match and what they can do

Limited gain access to rigs have actually boosted a lot in the last many years. The most valuable ones share three characteristics: modular components that may be held by finger or even pallet jack, reduced overall height, and also gas energy packs that can operate outside the building via hoses.

The smallest micropile gears break right into a mast, a rotating mind, as well as a foundation that may slip up via a 30 in door. Pole heights in the 7 to 10 feet array prevail for reduced headroom. Twist capability may vary from 4,000 to 20,000 feet pounds. Along with collision heads or even duplex systems, they may evolve examining while boring. For micro pile installation in very limited regions, I have utilized drill stands bolted to the slab, with distinct rotating drives, to keep the devices footprint tiny as well as stable.

For helical pile work, hydraulic travel scalps along with 7 to 30 kip feets torque can easily position on mini backhoes, compact track loaders, or stand-alone poles. In medical centers and retail atmospheres our team often change to electric power packs, which lower noise and exhaust. A 15 kip feet disk head with a counterbalance may set up 2.875 in to 3.5 in shafts reliably in strong clays, provided predrilling is limited.

Resistance stacks rely upon hoisting structures as well as braces, so the key equipment is actually low key gas cyndrical tubes, response frames that accommodate under the footing, and tracking devices for airlift. For interior work the challenge is actually sequencing ports so the construct carries out certainly not bind. I prefer spreader beams all over joists to distribute reaction when local area piece toughness is questionable.

The limiting variable is commonly punching liquid and spoil management. For micropiles, our team utilize pressed air, water, or even no fluid, depending on solitary confinement and also casing. On interior projects, our experts generally stay away from flush that can easily get away from past the hole. Vacuum cleaner wraps at the casing head perform a great deal of massive training to maintain floorings clean. For helical and protection systems, the spoil is actually minimal, however cuttings coming from predrilling or utility potholing still require containment. Plan on ongoing housekeeping as well as bad sky devices if dirt is actually sensitive.

Methods that lessen danger under reduced headroom

Methods matter greater than brand names. A handful of rules of thumb always keep minimal access service timetable and out of trouble.

Pilot examination often, early, and in the worst section of the internet site. On a transit hub retrofit our company piloted pair of micropiles in the end of a narrow hallway, certainly not at the very easy side near the door. Our experts located a hidden piece as well as a layer of slag that will possess ruined creation bits. Our company adapted to carbide ring bits and also brief housing as well as prevented dropping a time later.

Control positioning with basic jigs. In limited rooms, a half-degree of misalignment over twenty feet can easily place you into a beam or even a pipeline. Our company use steel practice layouts taken flight to the piece, with compatible bushings at the style angle. Layouts allow tidy reentry after lunch, even when the equipment has actually relocated around.

For grouting, match mix as well as technique to the purpose. If you need to have higher connect, cool concrete with water concrete proportion in between 0.40 as well as 0.50 pumped from all-time low up by means of a tremie is actually standard. If you have caving sands, think about ultrafine concrete or even a much higher thickness grout to lower washout. Post cement when bond size should be maximized in rough soils. For a storage facility row line where our team needed to have 200 kips per turn in antarctic sands, our company presented primary grout, after that light bulb grouted at 10 as well as 15 foot intervals. Confirmation testing revealed a 20 to 30 percent capability increase versus the key only.

Track torque and stress as if your routine depends on it, due to the fact that it carries out. For helical piles, torque is the substitute for ability. Adjust the twist surveillance, and established very clear stop criteria: either reached aim for twist over the last 3 feet or stop at deepness limitation and reassess. For micropiles, log housing innovation stress, rotation speed, cement pressure, and take. If grout tension spikes, you may be connecting. If take mosts likely to absolutely no all of a sudden in a sand lens, bond beliefs might be wrong. Industry data provides you alternatives prior to rebar and grout are committed.

Helical tieback anchors in business basements

Many commercial foundation repair jobs include lateral stabilization. Stooped cellar walls as well as top-of-wall displacement develop in much older frameworks with superficial grounds and backfill that holds water. Helical tieback anchors put up by means of the wall structure, typically by means of core-drilled openings, as well as bunch back to deadmen in proficient ground. On a 1930s institution makeover, we could not bring a crane for soldier piles. As an alternative, our team drilled 3 in holes by means of the wall structure at 5 feets on center, put up helical tiebacks at 15 to 25 degrees below parallel, and also torqued to 8 to 12 kip feets to reach design tons of 25 to 40 kips every anchor. Inner parts waler light beams circulated tons. Sound never rose above 80 decibels, and also classes proceeded upstairs.

Key details: match helix configuration to the ground so the lead carries out not overload and also slow. Make use of expansion shafts along with corrosion security for long life span. Grouting tiebacks is actually a thinking phone call. In non-caving clays, ungrouted helical anchors carry out properly. In sands, a cement pillar around the support shaft can easily boost capacity and also rigidity. For commercial helical tieback anchor installation in harsh grounds, hot-dip galvanizing or epoxy layers are worth the small premium.

Underpinning with protection stacks inside a live building

Resistance heaps underpin grounds through mounting pipeline sectors till the pile tip finds qualified bearing or skin rubbing builds adequately. In a clinical office where resolution broke gypsum partitions and doors put, our experts put in resistance heaps along the interior footing lines after sawcutting accessibility ports in the slab. Each brace was actually anchored to the ground with high stamina bolts. Load sectors accelerated with a 60 ton port up until the stress maintained, normally in between 3,000 and 4,500 psi on a 60 straight in ram for the tons our experts anticipated. Our team at that point transmitted tons to the braces as well as elevated a part of an inch to shut structure splits. Keeping track of with dial determines on pillars kept the airlift uniform.

Resistance heaps feel to the body weight of the building. When the footing is actually softly packed, the jack slows before reaching capable strata. The work-around is to phase braces as well as include brief response, but complication rises quickly. In those cases, micropiles or even helical piles commonly offer an even more predictable path.

Installing micropiles in phases around operations

The least flexible component of internal micropile work is logistics. You may certainly not assume available setting up and also easy crane choices. Materials get here cut to length or even basically segments, encouragement is actually entwined with couplers, as well as whatever carry on carts. Intend on a tidy path from presenting to the job face. If you are establishing twenty micropiles inside a data facility along with hot and cold aisles, one misstep with a cement hose pipe may ruin your week.

Hidden energies are the most significant danger. Personal utility locates are actually not ideal, as well as prepares hardly reveal every thing. Our company consistently pothole at each place to 5 or even 6 feets with suction digging or small size pilot boring, at that point change fully size. In an older manufacturing plant, we discovered a 3 in process water line 18 inches off the ground that no sketches presented. That a person pothole spared an unexpected emergency shutdown.

Schedule usually tends to stretch if grout remedy times are certainly not handled. In cooler insides, a 0.45 water concrete proportion grout may get to style durability in three to 5 days, yet access constraints require much faster turn over. Higher early mixes, accelerators, or even staged steel setting up can maintain creation moving. When the project requires lots screening, organize the test piles near the door to make it possible for early demobilization of the examination frame.

Load screening as well as quality control you may perform in tight quarters

Verification as well as evidence testing carry out not go away considering that the ceiling is low. For micropiles, static squeezing or pressure tests with gas ports and response structures suit remarkably tough areas. A popular create uses two reaction overdo either side of the exam stack, a spreader shaft, and also a port. The tons cell and also variation transducers feed a record lumberjack. For a bank fit-out with 9 feet ceilings, our company used a modular reaction frame that constructed in parts as well as suit a minivan for distribution. Test loads were actually 1.5 times solution for verification, with creep upheld defined rates.

For helical piles, stress testing with a transportable response framework verifies torque connections. A basic A-frame supported to piece anchors may react helical pile foundations 30 to 60 kips safely and securely if created adequately. Resistance piles are tougher to evaluate separately, however disk stress at refusal, jacking logs, as well as airlift observations create the acceptance manner. No matter device, depend on a quality control strategy along with checklists for torque calibration, grout batch tickets, mix temperature levels, and also bar warm numbers.

Nondestructive choices exist in close quarters. Crosshole sonic logging is certainly not relevant to small diameters, but low-strain stability testing can determine disgusting flaws in micropiles if you have a crystal clear head on the stack scalp. For tiebacks, lift-off tests after the cement has actually healed verify support lock.

Dealing along with foundation cracks as well as tons transfer

Foundation fracture fixing is often what delivers our company to the internet site. Cracks are symptoms, not the health condition. Carbon dioxide Click for source fiber straps or even epoxy injections may stitch or even seal cracks, but unless the cause is dealt with, they are going to come back. After founding with micropiles, helical piles, or even resistance piles, our company at times decrease action enough that fracture fixing becomes heavy duty. For shear splits at corners or even near positions, take into consideration including steel brackets or needle beams that link back right into new deep elements.

Load move coming from old footings to brand new deep components is where breakdowns occur thoroughly, certainly not in piles. Birthing plates require adequate region as well as supports to prevent neighborhood obliterating. If the existing footing is thin, distribute bunch with a brand new cap ray of light or even a floor covering. For a commercial foundation stabilization under a 14 inch ground, our experts set up a 6 inch cement floor covering beneath along with ground compaction grouting, then established brand-new micropile heads as well as cast a 12 in limit light beam tied right into the ground along with pegs. Action after tons move was less than 1/16 inch.

Noise, vibration, and also dust: the working realities

Commercial areas are inhabited. A medical facility's MRI room adjacent, a law workplace above, a storekeeper on the first flooring. That implies noise, resonance, as well as dust control are not negotiable. Micropiles, put in appropriately, produce reduced vibration contrasted to steered units. Helical piles and anchors are quieter still. Resistance piles demand mounting, which can easily generate some creaks in framework, but degrees are actually manageable.

Noise coverings, rubber floor coverings under energy packs, as well as scheduling loud procedures for mornings aid. Adverse air machines with HEPA filters, taped joints at temporary wall structures, and dedicated fragments routes always keep dirt contained. Planning your slurry and also washout monitoring. A covered blending area with spill control, and also a washout bin that suits by means of doors, prevents ugly unpleasant surprises along with structure management.

Vibration limitations commonly show up in the specs: 0.08 to 0.20 ins per secondly for delicate equipment. Our experts position seismographs in neighboring areas as well as established triggers. When market values come close to limits, our company alter approaches, slow-moving turning, decrease percussive activity, or switch to helical units if suitable. Communication with renters is actually as crucial as instrumentation. Daily notifications along with organized noisy periods can save your workers from receiving stopped by a home manager.

Corrosion, longevity, as well as lifecycle

Commercial managers think in decades. Micropiles with steel reinforcement embedded in cement grout enjoy intrinsic alkalinity security. Where soils are actually hostile, our company indicate added cover, epoxy layered threadbar, or even long-term housing that stays in position. For helical piles, priming and epoxy prevail in harsh settings. In seaside websites or places with stray present, sacrificial density and also cathodic defense may be justified for critical elements.

Documentation concerns. Deliver the owner with cement mix styles, heap logs, torque logs, product plant certs, and also a basic narrative of what was mounted as well as where. Potential occupants and designers will certainly thank you when they open the flooring and question what those steel scalps belong to.

Cost and also schedule requirements that delay in practice

Owners request a square feet rate, but these units cost through element and also mobilization. For planning, internal micropiles with proof testing in urban settings frequently land in the variety of mid four to low five bodies per heap depending on deepness and also support. Helical piles for interior work could be lesser, especially for lighter tons as well as briefer lengths. Resistance stacks are competitive for underpinning when reaction and also accessibility are favorable.

Schedule is steered through coordinations and also cure opportunities. A small indoor micropile staff may put up three to eight heaps each day, depending upon case, intensity, as well as ruin monitoring. Helical teams commonly beat that pace, mounting six to twelve heaps per day in friendly soils. Resistance pile crews might underpin three to six braces each day. The vital road runs through material purchase, screening, as well as load transfer. Always keep that in mind when vowing times matched to resident turnover.

Two compact checklists that always keep minimal gain access to work on track

Preconstruction fundamentals for restricted access piling:

- Confirm clearance, door widths, as well as transforming radii along with a videotaped site walk, certainly not assumptions. Locate as well as fracture electricals at every pile, consisting of personal lines, just before full-diameter drilling. Choose the system that matches dirts as well as restraints: micropiles for obstacles and also higher lots, helical piles for rate in even soils, resistance stacks for underpinning along with sufficient reaction. Lock down sound, vibration, and dirt protocols along with property administration and tenants. Plan grout strategies, washout, and also daily housework as carefully as load calculations.

Field implementation cues for micropile and also helical installation:

- Use drill templates and also positioning jigs to manage disposition in reduced headroom. Log torque, stress, deepness, and also cement consume real time; stop as well as reassess when worths deviate. Protect encouragement along with sufficient cover and also effective splices; carry out not require bar by means of limited casing. Verify ability along with on-site screening scaled to the venture, at that point hold the acceptance criteria. Sequence load transfer properly, checking motion with determines and also lasers to steer clear of binding.

When micropiles are the only rational choice

Despite the assortment of tools, there are actually cases where micropiles are actually merely the right solution. Historic brickwork where vibration is actually unacceptable. Mixed fills with block, ashes, and also hardwood that would damage helical tops. Web sites along with uplift as well as lateral demands that call for struggling sets. Deep-seated, thick strata that need exploration as well as grouting to activate connect. In those environments, an effectively organized micropile installation brings certainty. The devices fits through doors, the workers can easily function under lightings rather than skies, and the lots transmit into trusted ground.

Commercial foundation repair work is as a lot choreography as design. The best end results stem from lining up layout intent along with the realities of a cramped mechanical room or a live retail flooring. Pick the unit that values the restraints. Take devices that truly matches. Carry out strategies that foresee the mistakes. Do that continually, as well as micropiles, helical piles, protection piles, and tieback anchors end up being silent history players in a structure's next section, performing the hefty lifting while commerce carries on above.